Features

Characteristics

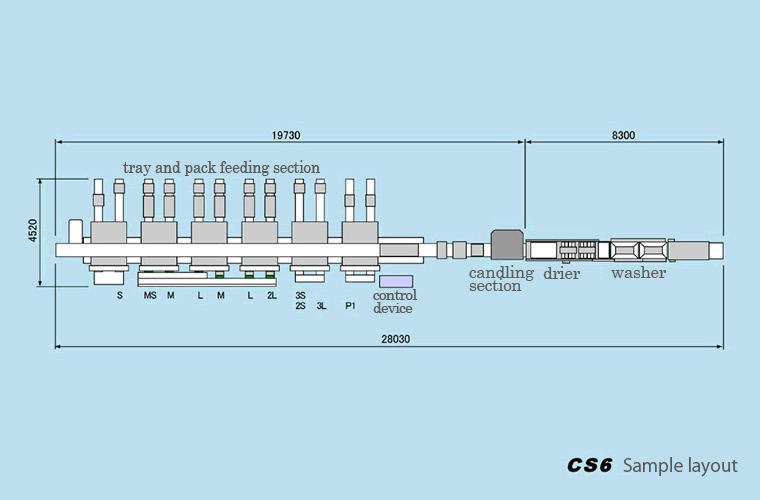

Sample layout

Specifications

| Type | |

| Processing speed | |

| Electric power | |

| Hot water supply | |

| Water supply | |

| Air compressor | |

| Electric power and Air compressor are reference value of standard type. Neither peripheral equipment nor optional equipment is included on the above specifications.Please contact our sales staff for details. | |