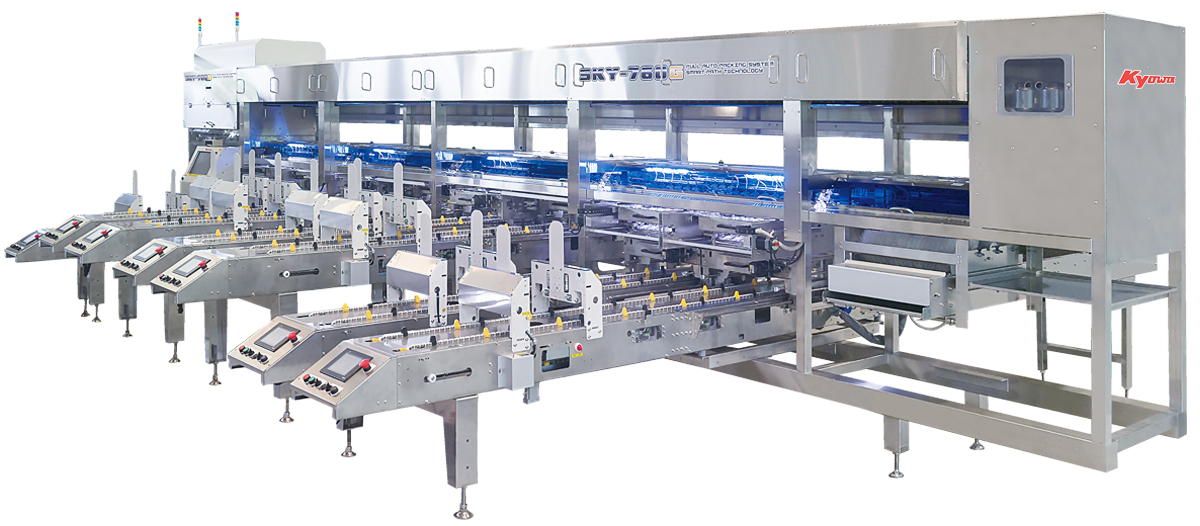

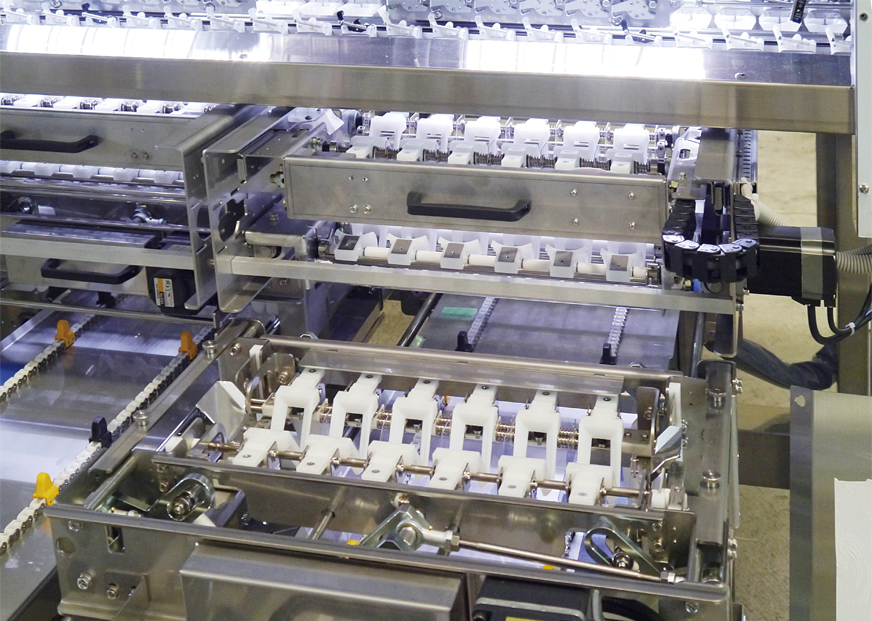

Features

Characteristics

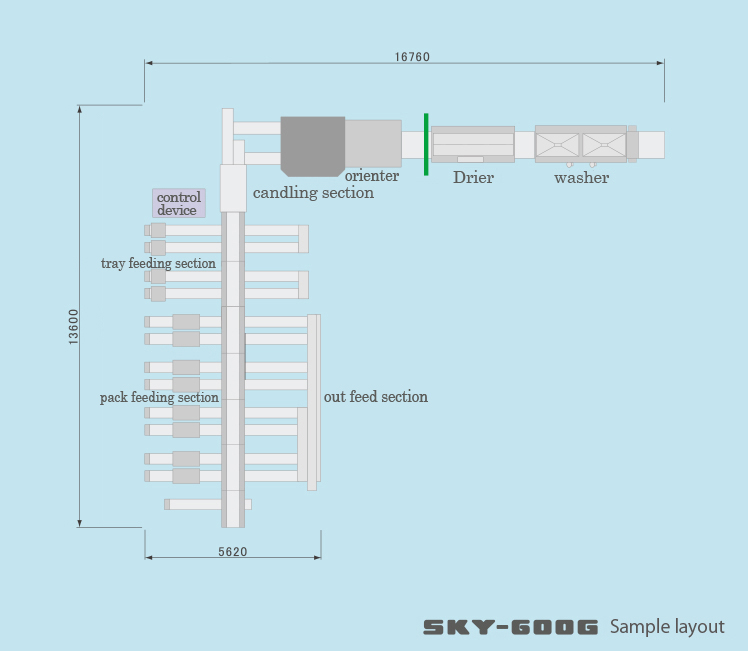

Sample layout

Specifications

| Type | |||

| Processing speed | |||

| Electric power | |||

| Hot water supply | |||

| Water supply | |||

| Air compressor | |||

| Electric power and Air compressor are reference value of standard type.Neither peripheral equipment nor optional equipment is included on the above specifications.Please contact our sales staff for details. | |||